Capability

Investment Casting

At our investment casting foundry in the UK, Sylatech has been manufacturing precision investment castings for over six decades. We deliver a lost wax casting engineering solution, within the AS9100 quality standard that is suitable for producing small, lightweight cast components, for the most challenging product applications.

Experts

Precision Investment Castings

Our specialist lost wax process affords us the ability to take a customer’s concept and achieve reality in a fast and cost-effective manner. By combining our investment casting technology with best practice CNC machining, our capability can overcome many of the constraints placed on engineering design.

The Sylatech investment casting process provides a fast and cost-effective method for both small batches and high volume quantities. Parts with complex internal and external detail, super-fine surface finishes, and thin-wall capabilities, can be produced without the need for machining from solid.

Benefits of Sylatech's Investment Casting Capability:

- Reduce overall costs by Designing for Manufacture: simplify an assembly by combining a number of parts, eliminate joining processes and reducing the part count, whilst improving the integrity of the finished product

- Reduce time to market through the use of additive manufacturing technology, and obtain investment casting, machining and assembly parts from one source. Finished metal parts can be delivered from concept in under four weeks

- Design flexibility, with fast modifications to tooling, that costs 90% less than for a pressure die casting, whilst maintaining high volume economic batch quantities

- High quality finish, detail and specification.

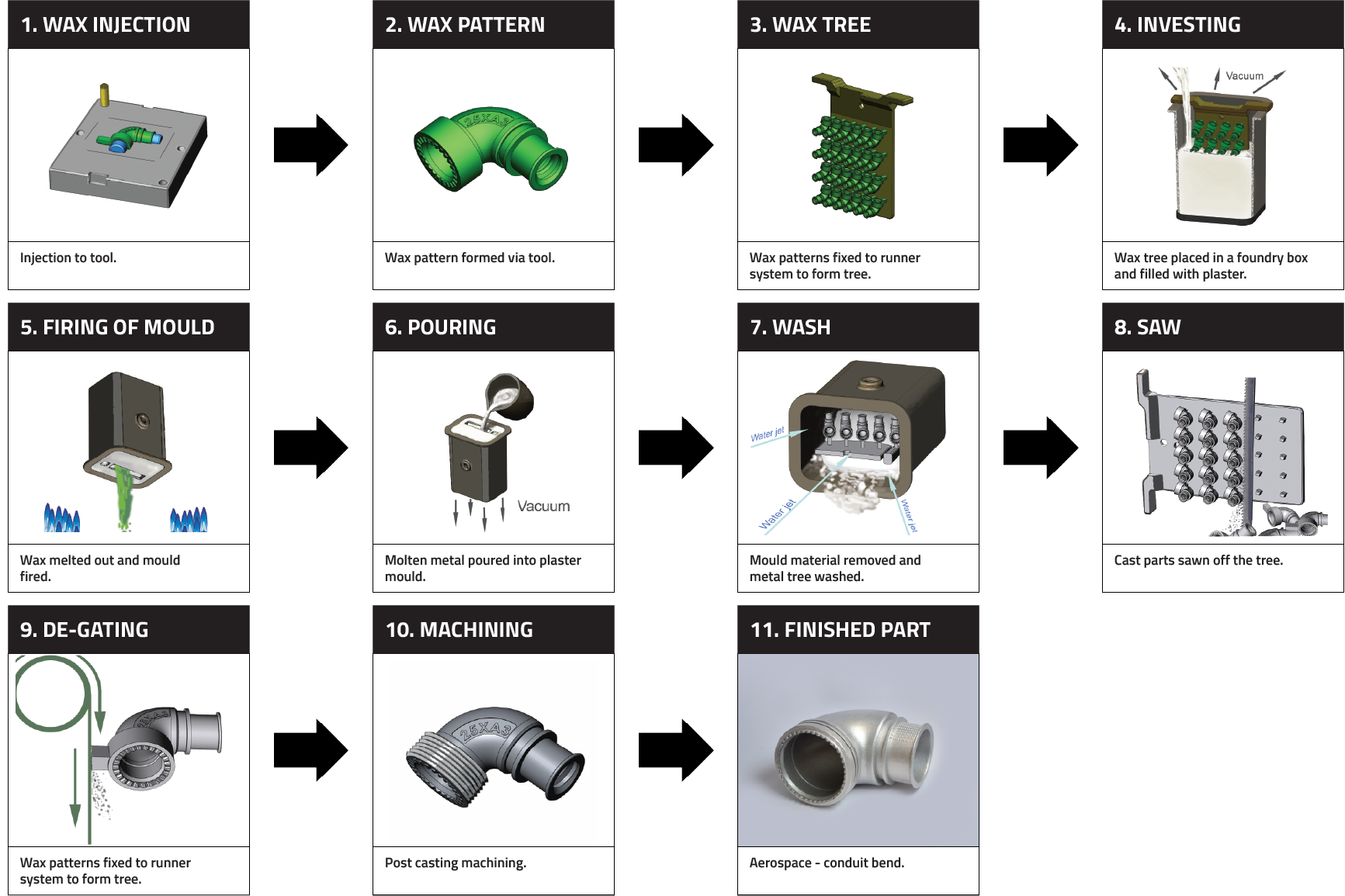

Investment Casting Process

We utilise a block-moulding version of the lost wax casting process. The plaster penetrates all external features and fills internal voids to ensure that, as the mould is formed, every detail of the wax pattern is faithfully reproduced.

Process Capability

What can the Sylatech precision investment casting process deliver?

- Thin-Wall Capability - Walls as fine as 0.2mm (0.008”) can be produced, typically 1-3mm (0.04” – 0.12”)

- Lightweight Components - Components weighing as little as 1g can be produced using techniques to retain component integrity

- Small Precision Castings - Ideally a maximum size of 190mm x 160mm x 160mm (8” x 6” x 6”). Larger sizes can be considered on a case-by-case basis

- Super-Fine Surface Finish - Surface finishes with 0.8 micrometres (32 micro inches) being the “as cast” finish. Zero draft angle.

3D Printing for Casting

Sylatech uses 3D printing to prototype metal parts for it’s customers, allowing them to test their designs without having to invest in tooling ahead of casting. This yields significant time and cost savings, resulting in fewer future tooling modifications being necessary.

- Complex geometrics parts, in production volumes

- Flexibility in the product design lifecycle

- Time and cost savings

- Accelerated placement of tooling orders

- Reduced level of tooling modifications.

Metals we cast

Customer example

When an incumbent casting supplier was failing to deliver, an engineering solution for a complex aerospace impeller was urgently required. The team at Sylatech were rapid in their response and followed a staged process to address the customer’s demands.

Our Approach

Understand the dynamics and challenging geometry of the part

Creation of in-house 3D printed rapid prototypes in wax

Development of a custom pouring technique for casting of prototypes

Approval of process to achieve stringent NDT requirements, including dye-penetrant testing and x-ray

The process from initial contact to samples for assessment took place within four weeks.