Hybrid Additive Manufacturing

Sylatech’s hybrid additive manufacturing capability enables engineers to design and produce high-accuracy components with exceptional detail and repeatability. Whether you’re developing an early-stage prototype or manufacturing production volumes of complex geometries, our additive processes deliver the freedom, speed, and reliability required for demanding applications.

Experts

Turning design freedom into reality

Sylatech’s additive manufacturing uses advanced 3D printing to create intricate wax and resin patterns for high-precision metal parts. Free from tooling constraints, engineers can achieve lightweight, thin-wall, and complex geometries with fast turnaround and consistent accuracy.

Key Benefits

- Unmatched design freedom and geometric complexity

- Rapid, tooling-free prototyping

- High-quality surface finish and precision

- Smooth transition from concept to casting.

Hybrid Additive Manufacturing

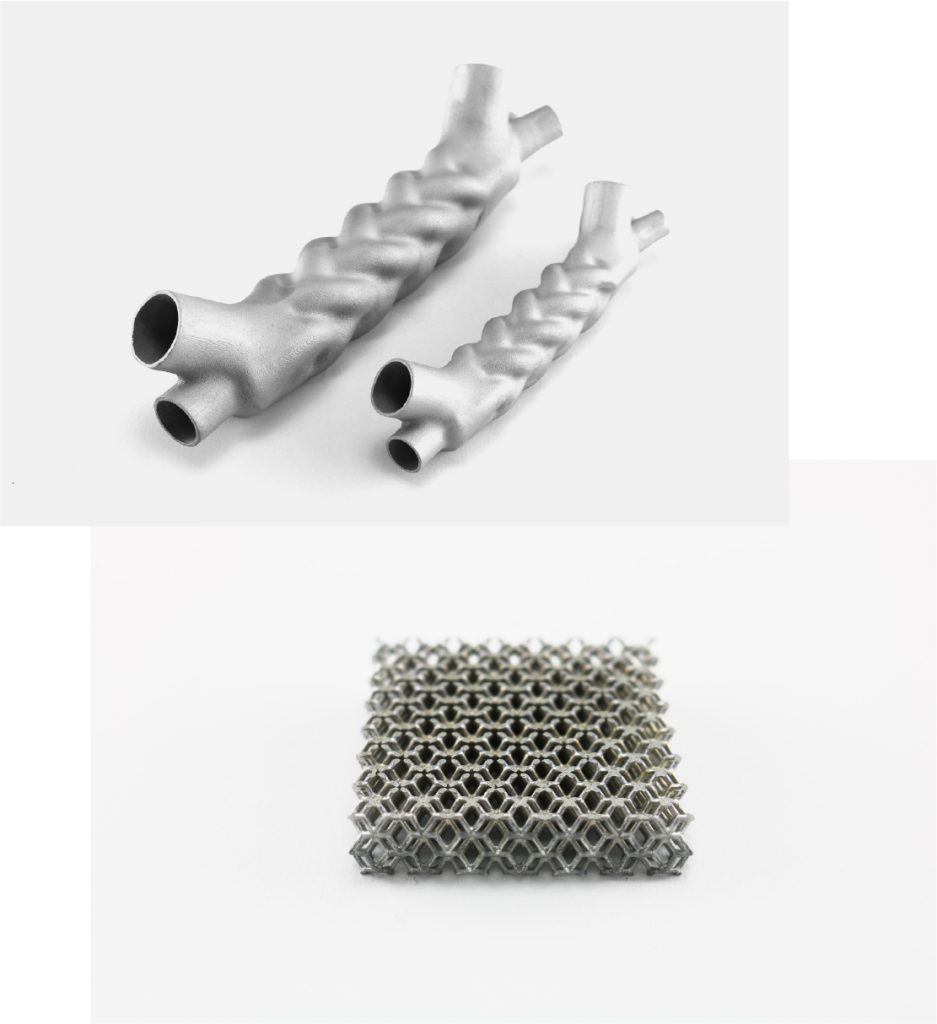

Complex Shapes at Production Scale

Sylatech’s Hybrid Additive Manufacturing fuses the design freedom of 3D printing with the precision and strength of casting, enabling intricate metal components, from thin-wall structures to internal channels, that traditional methods can’t achieve. This integrated approach delivers complex geometries at scale, with production volumes of up to 5,000 parts per month.

The Advantages

- Complex geometries in metal – forms that can’t be tooled or machined

- Scalable production – cost-effective volumes from prototypes to thousands

- No tooling constraints – easy design changes and rapid iteration

- Integrated design support – DFAM and CFD modelling available

- Single-source process – from concept to full production with Sylatech

Rapid Prototyping

From Concept to Metal in Days

At Sylatech, rapid prototyping means precision components delivered fast. Our in-house additive systems create high-definition wax and resin models in hours, without tooling delays. These patterns are quickly cast into functional metal parts, allowing engineers to test, refine, and validate designs within days, accelerating time-to-market.

What This Means For You

- Prototype actual metal parts in a fraction of the usual time

- Eliminate tooling delays and rework costs

- Accelerate design iteration and product development cycles.

The Sylatech Advantage

From Idea to Production

Every project we undertake is supported by our in-house engineering and foundry specialists, ensuring that each additive or hybrid process is optimised for performance, efficiency, and cost. With design, prototyping, and casting under one roof, Sylatech provides a truly end-to-end manufacturing solution that helps customers innovate faster, reduce risk, and achieve repeatable production quality.

Example Hybrid Additive Castings

"From rapid prototypes to complex production runs, Sylatech empowers engineers to realise designs once thought impossible, combining advanced additive technology with foundry expertise to turn ambitious ideas into high-performance metal components."

Gordon Gunn, Commercial Director at Sylatech

Downloads

Should you require further information, please do not hesitate to telephone us on +44 1751 432 355.